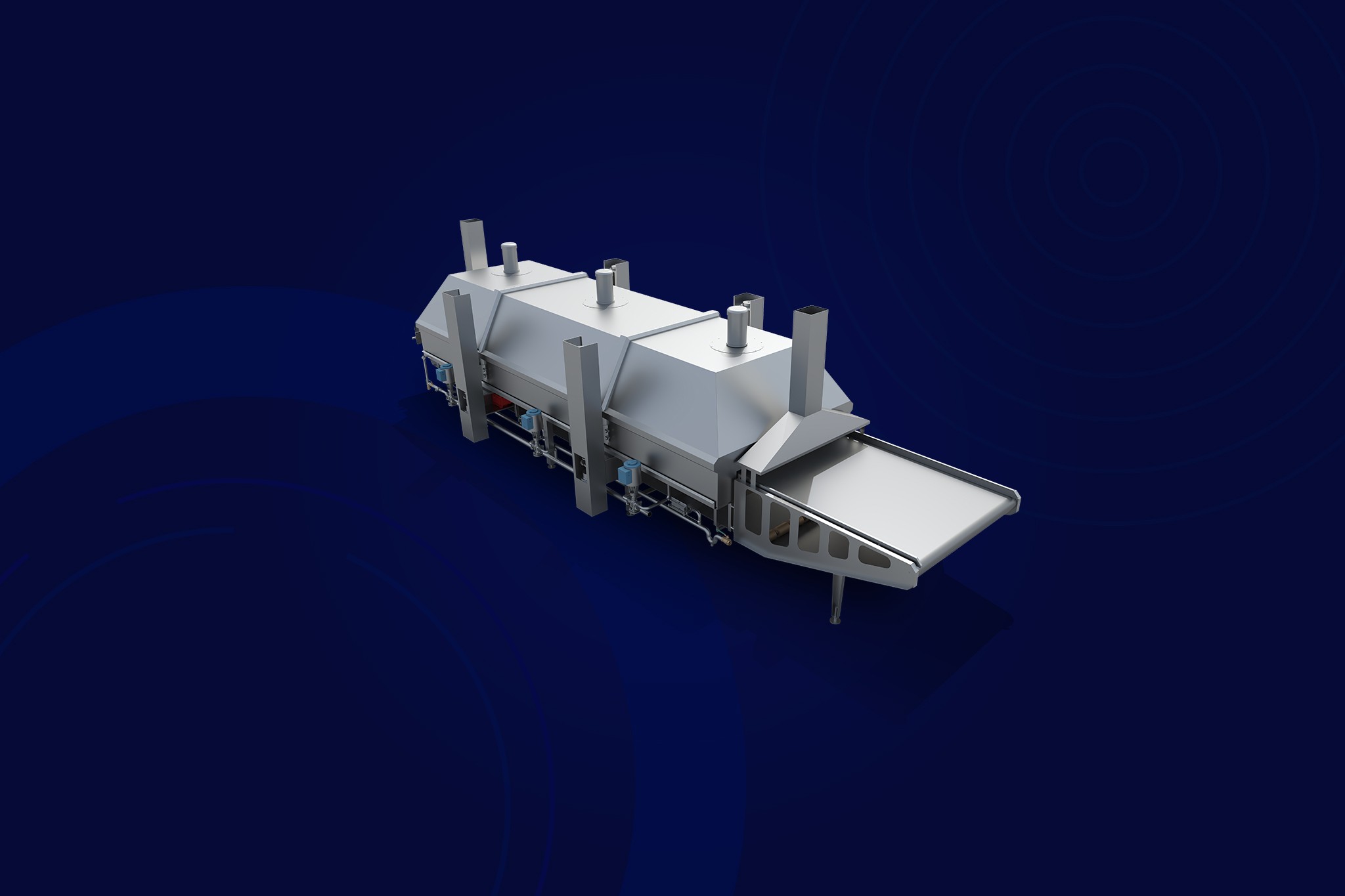

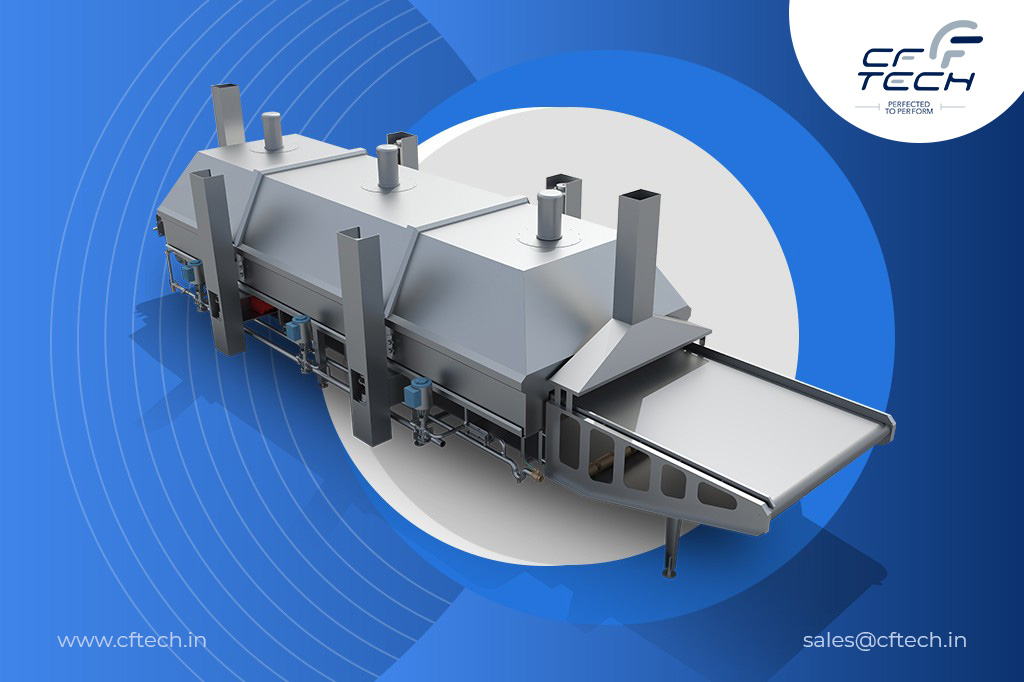

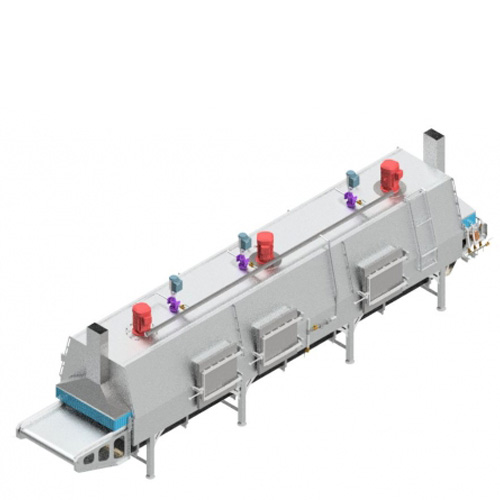

COOKING LINE - COOKER

Key Specification

• Excellent product texture and appearance

• Up to 8% higher yield

• Decrease energy costs by 25% to 85%

• Automatic hood lifting mechanism for easy clean

• Meets rigorous food safety and sanitary design standards

• Uniform, Consistent and predictable product temperature

• Cookers are easily configurable to meet specific customer needs

Overview

The cooker uses a forced convention method and the process consist of a low temperature mixture of

air steam and condensate water which is constantly circulated inside the chamber and distributes heat

uniformly and efficiently. The products are cooked, blanched or pasteurized consistently using less steam

than traditional methods, and helps in maintaining the high quality of the products.

The unique design as well as the PID controlled motorized steam valves and VFD controlled blowers ensures

that the cooking yield is always kept at a maximum and gives an energy savings better than any other cooking

method in the market. The Steam Cooker is manufactured entirely in stainless steel and non- corrosive

materials for providing the best possible conditions for quality processing. The twin layer insulated outer

body gives very little heat loss to the surroundings.